|

Taizhou Xingjian Energy-Saving Glass Co., Ltd

|

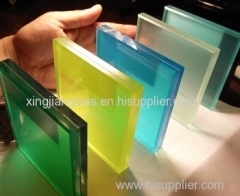

xingjian Silk screen glass

| Price: | 50.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Silk screen glass is the use of silk screen printing plate, use of glass glaze, Decorative printing on glass products. Glass glaze called ink glass.

Silk screen glass is the use of silk screen printing plate, use of glass glaze, Decorative printing on glass products. Glass glaze called ink glass, glass printing material, which is composed of pigments, binders and mixing into paste printing material. Coloring materials composed of inorganic pigments, low melting point cosolvent (lead glass powder); binders in the glass screen printing industry, commonly known as Lee suet.

After printing, glass products, tempering furnace, to 700-750 DEG C temperature is fired, printed onto the glass surface of the glaze to consolidation in the glass, the formation of colorful decorative patterns. If the silk screen printing and other processing methods and use, will be more ideal effect. For example, the use of polishing, engraving, etching and other methods before printing or printing on the surface of the glass processing, can increase the printing effect.

After tempering or high temperature baking ink and glass surface tightly together, unless the glass is broken, the pattern and the glass will not be separated.

Application range:

Screen printing plate glass application and market prospect of network printing plate glass is widely used in every corner of people's life: you can in the display window, partition of architectural space, beautify the appearance of the building, automobile windshield glass and mosaic glass, etc. easily find their shadow. At the same time, they are also widely used in furniture decoration and game tools, as well as countless decorative and artistic creation. Screen printing has become a part of the creative design work in glass manufacturing. People can use screen printing color images printed directly onto the glass surface. In addition, it can also be used to temporarily cover the glass surface of the non graphic part, or in the glass surface of the part of the regional printing preservatives and other additives, so that it is not affected by the process of etching or scrub. Relatively, but also can be directly printed on the screen printing ink, the production of etching or matte effect. Sometimes. People will also use the screen printing strong covering ability, such as in the glass printed on a layer of thin conductive material for window making anti icing (cream) device.

technological process:

Screen printing process of glass according to the principle of silk screen printing, the ink to the surface of the glass, and then use the ink curing measures, the printed pattern firmly durable. The process is as follows: tension and the network, sizing, drying, exposure, developing, drying, flat glass, cutting, edge grinding, cleaning drying, printing NaBH sintering 1. Suitable for printing glass according to user requirements for cutting glass, can be irregular in shape, also can be irregular in shape, then pour edge grinding, and cleaning, dry stand-by. Special attention should be paid to the glass surface can not have water mark. 2. Screen printing screen printing plate and the general screen printing plate, glass silk screen version of the selection of synthetic fiber, stainless steel wire mesh, natural fiber mesh. When printed on the general pigment, the screen may be, generally used in low price of synthetic fibre mesh; used as a gold and silver decoration, you can not choose stainless steel wire mesh. Wire mesh specifications generally use 300 ~ 270 mesh. 3. Net frame is more formal, deformation small net frame is aluminum alloy frame, the size should be than the pattern, specific size should is the pattern from the outer edge of the screen frame should be between 70 ~ 100mm. In addition, the selection of the net box, its strength is very important, the key is the horizontal direction of the rigid enough. 4. The tension and the network selection screen and screen frame, combine the two, this is the screen. Stretch network of many ways, uses the manual, mechanical, gas dynamic variety of ways, and the more advanced, will be able to stretch in a high quality screen is pneumatic stretching machine. The tension and the network is the requirement of uniform tension, the net thread keep vertical net gum to the firm, not loose